|

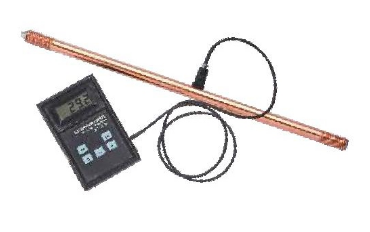

Copper Coating Thickness: All 100% rods (full production) are subjected to the coating thickness test. Every rod at several points is checked by an electornic thickness tester to measure the copper thickness on the steel core. The reading in case of UL listed rods is not less than 254uM and for other rods as specified by the end user. |

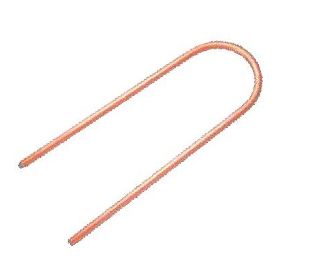

| Bend Test: The bend test is carried out by a rod bending machine to provide an equal force at all points. The rod is subjected to bent up to 180 Degrees. The copper sheath should not crack or tear at any point of the rod. |  |

|

Adhesion Test: An 18-inch length of the rod with on end cut to a 45 degree point shall be driven between two steel clamping plates or the jaws of a vise, set 0.04 inch less than the diameter of the rod, so as to shear off sufficient metal to expose the bond between the jacket and rod. Peeling of the jacket by the steel plates or the jaws of the vise is acceptable, bu there shall be no other evidence of separation of the jacket from the steel core. |